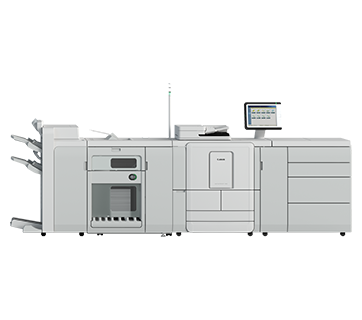

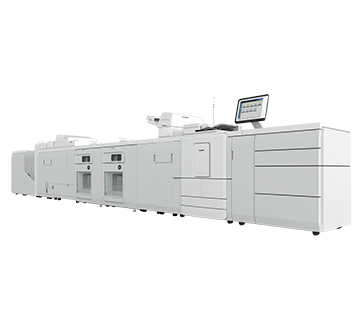

Configure the varioPRINT DP line to meet your requirements in terms of speed, scanning, paper input, finishing options and workflow support. Start with a basic system and upgrade to a higher level of performance. Or replace multiple machines with one all-digital, multipurpose device.

Three speed levels are available to address light to mid production requirements.

No matter what the speed, duplex performance is always 100% and auto duplexing for media up to 300g/m2 is available.

Black & white and colour scanning allow you to offer advanced services with several scan-to options.

- Scan-to-file

- Scan-to-Email

- Scan-to-DocBox

- Scan-to-FTP

- Scan-to-USB

The system offers numerous paper feed features that allow you to ramp up and down to meet changing production requirements.

- Four standard paper trays

- Optional external paper input module with single or dual paper trays

- Support for a wide range of media sizes and weights

- Automatic size detection in all trays

- Paper Logic ensures correct media orientation

Customers want more than a stack of paper. They want professional, high-quality documents. That’s why the varioPRINT DP line offers various finishing options that can be integrated into one end-to-end solution.

- Stapling

- High-capacity stacking

- Folding

- Punching

- Preprinted inserting

- Booklet making

- Glue binding

You can configure the PRISMAsync controller and user interface exactly the way you want. Set the required language, choose the processing modes that fit your current workflow and add options when needed. Depending on your production needs, you can make the Schedule, job editing and DocBox functions available to operators. And when your workflow requirements change or grow, you can incorporate further PRISMA software modules.

The varioPRINT DP line combines clean-sheet print technology with the industry-leading PRISMAsync controller. This gives operator intuitive workflow for immediate productivity, minimal learning curve and easy management of the most complex jobs.

- Operator panel integrates controller, user interface and engine

- All system functions and settings accessible from the colour touch screen

- Configure the system to drive production printing, scanning and copying, and advanced job editing

- User interface displays the total production schedule

- Colour coding alerts operators to upcoming interventions like media refills

- Intelligent job scheduling for uninterrupted production and smooth workload planning

- Customized, define-once media catalogue includes all media settings

- Paper Logic ensures correct media loading including preprinted or pre-punched stock

- Virtually eliminates errors and media waste

- One operating concept ensures consistent job handling for printing, scanning and copying

- Operators spend less time at the machine

- Staff are more efficient

- Reduced training costs

- Higher productivity

- Advanced document preparation at job and page level from the operator panel

- Make last-minute changes at the printer without going back to prepress

- Run jobs from Kodak Smartboard and Xerox FreeFlow MakeReady workflows without losing job ticket settings or media attributes

- Full integration with PRISMA workflow solutions

- Single point of control

- Intuitive, award-winning user interface design

- State-of-the art job and queue management

- Predictable production planning up to 8 hours

- Adobe PostScript 3, PDF 1.7, PCL 6, XPS, IPDS, PCL6/PJL

- Advanced editing options at job and page level

- Uniform handling of copy, print and scan